Technology

The regasification Terminal FSRU Toscana was realized using safe and fully tested technologies with subsystems and components that are widely used in the various sectors of the oil and gas industry.

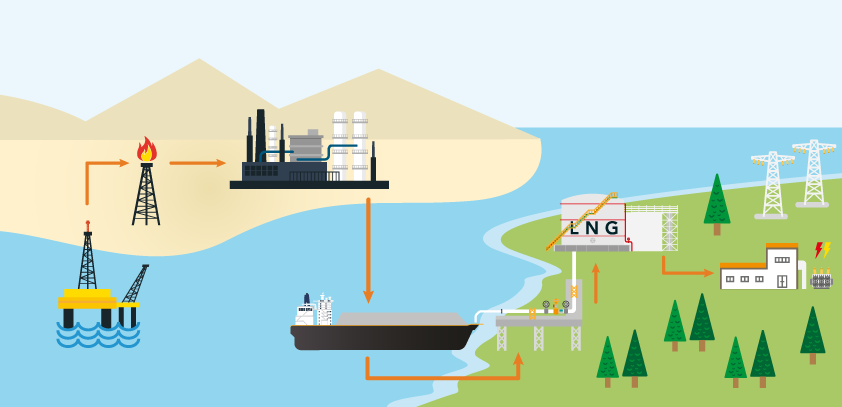

The regasification system consists of liquefying the natural gas in producer countries to enable its transportation by LNG carriers to consumer countries; here it is then reconverted into natural gas.

To allow this type of transport, the gas extracted is cooled at a temperature of -160 °C to liquefy it, reducing its volume of more than 600 times. Therefore, a single LNG carrier can store a big quantity of gas making transport economically sustainable. One LNG carrier can usually transport up to 266,000 cubic meters of LNG, which corresponds to almost 160 million cubic meters of natural gas.

LNG reaches by sea the consumer countries where it is reconverted into natural gas – as to say, regasified – and sent to the National Grid. The regasification process consists of sending the gas into a “heat exchanger” where a warmer liquid, usually seawater, flows and heats the LNG reconverting it to natural gas.

Transportation by sea is a suitable alternative to freely purchase gas in the world without being constricted to a gas pipeline connection with producer countries.

- Gas extraction in producer countries

Gas is cooled to be liquefied (LNG) and trasported. - LNG carriers transport the gas to the consumer countries allowing them to be independent from gas pipeline network.

- LNG is reconverted into natural gas by regasification plants and inserted in the gas transportation and distribution network.